Menu

Our current COMPETITION: Great prizes for divers and fire departments.

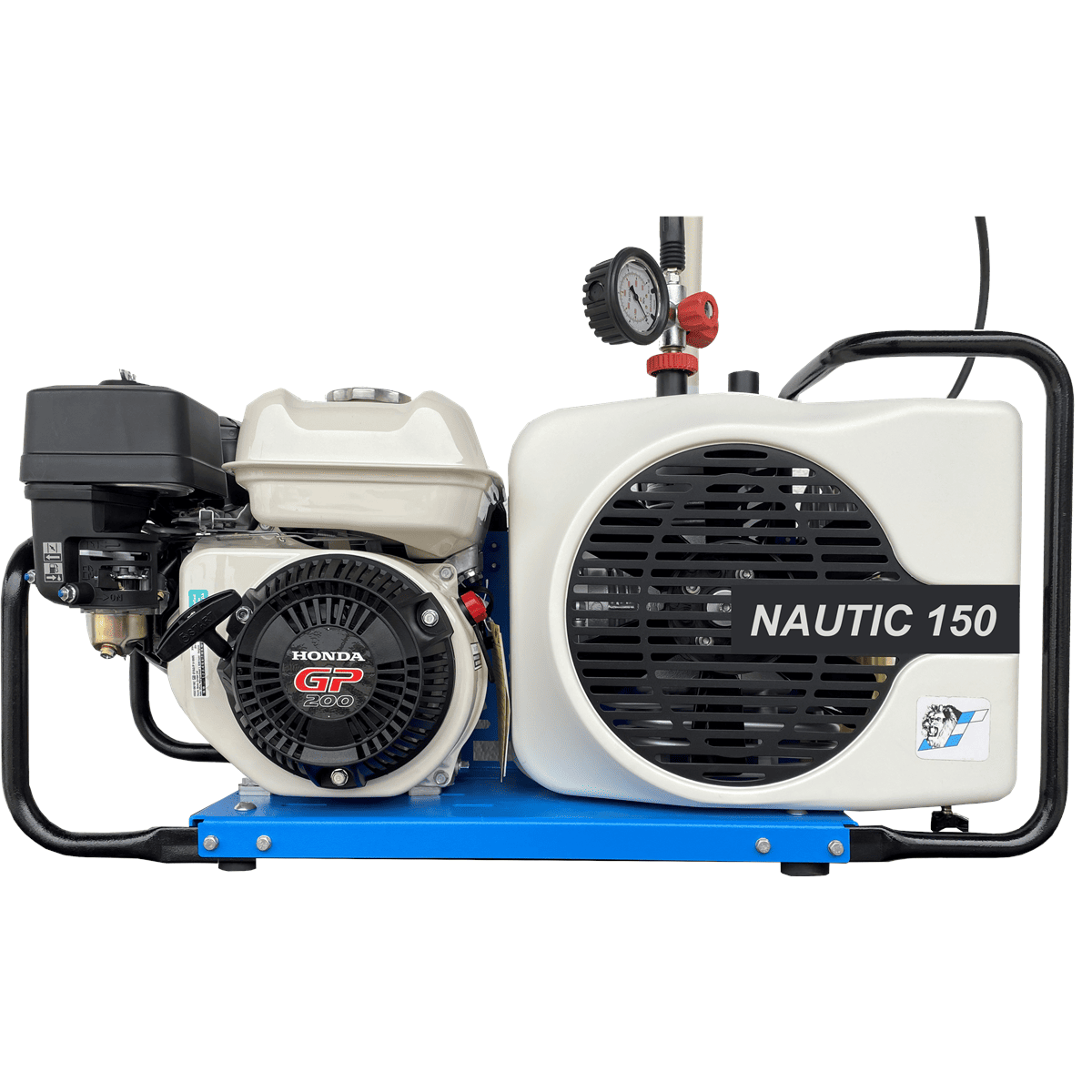

... as a diver you buy something when you buy a mobile breathing air compressor. We tested the NAUTIC PRO 150 model from IDE.

My personal dream has always been to be able to fill, empty and refill my two “12s” at any time, regardless of the opening hours of my diving or compressor shop. Simply load all the junk into my van and drive off - with the gas station for the tanks in my luggage. I was now able to fulfill this dream. Unfortunately only for about two months and the associated twelve dives/double tank fillings. First of all: Unfortunately, the compressor ended up back at the manufacturer after the test. Well, not quite. A friend of mine owns a company that does underwater work and then bought the test compressor. Why? On the one hand, because he needed a new, mobile device. And because he was also allowed to test and use the “Nautic Pro 150” from IDE to fill his storage bottles for the helmet diving device. But one after anonther. First impression The gasoline-powered version of the compressor reached us in a wooden transport box. For really “fit” buyers, the box weighs just under 60 kilograms and is portable, but this is not recommended. When unpacked, the “Nautic Pro 150” weighs 48 kilograms in our gasoline engine version and a maximum of 52 kilograms in the electric version. Although strenuous, it is still possible to carry the device from A to B single-handedly. Visually, the first impression is good in terms of workmanship and material quality. Our scope of delivery included: tools, the operating instructions for the Honda petrol engine and the compressor block, a filter cartridge, the first oil filling including oil and oil fill funnel for the first oil change and a DIN/INT adapter, the attachment pipe for the air intake and of course the filling hose including finish. In use Before the first use, installing the filter cartridge (type: VM 103 00 100H) is on the to-do list. The tools required for this are included in the scope of delivery. According to the manufacturer, the filter cartridge should be changed after 25 hours of operation (at 20 degrees Celsius). It therefore makes sense to create a small notebook for the compressor to note the filling times and quantities. Alternatively, digital operating and filter monitoring is available for retrofitting for 355 euros. Quickly checked the oil level. Here the manufacturer specifies the first oil change after 50 operating hours and then every two years. Of course, our model still needed gasoline (three liters). For the Honda engine (GP200) with 5.58 hp, there is an optional separate operating hours counter with tachometer (around 150 euros). Finally, the extension tube for the intake filter is attached. After all the preparations, the first filling begins. For this purpose, the filling valve is mounted on the bottle. When it comes to the filling valves, you can choose the 200 or 300 bar version depending on the compressor version. It is also possible to install a second filling hose. We connect our twelve liter 200 bar bottle to the valve and open the bottle. Set the petrol engine to “ON”, set the speed controller to full power, open the petrol tap, pull the cable. And lo and behold! It works. The compressor and petrol engine chug along not really quietly (according to the manufacturer 95 dB). If you're like me and are thinking about quickly filling your tanks for a Sunday dive, you should either do it at the dive site or hope that your neighbors will tolerate noise. We stopped time during the filling process. And, oh wonder, the manufacturer lied! In fact, according to our measurements, the Nautic Pro 150 delivers 152 liters per minute. That's a whopping 8.6 percent more (!). Prerequisite: You give the machine the starting pressure of 200 bar and then open the cylinder valve. Once the maximum pressure is reached, in our case 225 bar, an automatic system switches off the entire device. The bottle is closed and the filling valve on the pressure gauge is vented. Then all de-condensation separators on the filter are opened. A note on the filter housing says that the condensation valve must be opened every 15 minutes. So actually after every complete bottle filling. Caution: The condensation water splashes out. If you forget to vent, the device will be noticeable the next time you use it - it won't start. Once again, caution is advised as the operating temperature reached has heated some components to the point where they cannot be touched. Feedback and improvements “You quickly become operationally blind,” was the manufacturer’s comment on a few small points that we noticed in practice. Firstly, the point mentioned about the “heat”. We noticed this at the moment when the device was supposed to be stowed away again shortly after use. Reason for the unpleasant contact: Our device version still had device brackets that were installed too close to the functional units. The new models no longer have this disadvantage. Here, the distances between the bracket and the housing have been increased so that you can easily access and transport the device even in not so “hot places”. Even when bleeding the second stage, the valve was installed in an awkward downward direction. Was changed. Now there is only one point left that is a little more difficult to solve and that, as far as we know, other mobile compressors also have on the list as a shortcoming: The attachable intake pipe is somewhat vulnerable due to the material (plastic), and the filter Pipes also have no rain protection. In our case, the compressor was used for underwater work, even in bad weather. Water ran into the pipe and caused the air filter to get wet. But that was about it that we noticed as a “negative little thing” after our test run. Calculated Let's come to the second most important point: the price. For our petrol version, at 3,450 euros (plus VAT), it is within a “pleasant range” and, given the 140 liter air delivery capacity and the five-year full guarantee, it should be at the top of the price-performance ratio in a direct market comparison take in. But is such a purchase worth it as a “private person”? Let's do some quick math. Today, filling a bottle in the shop costs between 50 and 70 cents per liter of bottle volume (200 bar filling). So with 60 cents for a twelve liter bottle you get at least 7 euros on average, but also 9 to 12 euros. For our petrol engine, in addition to the pure device costs, there are also: filter cartridge (30 euros/25 hours corresponds to 2 cents per minute of operation times a maximum of 15 minutes per bottle filling) 30 cents, consumption (0.03 liters per minute times 2 euros per liter times a maximum 15 minutes filling time per bottle) 90 cents. If we ignore oil consumption, we come to pure additional costs of 1.20 euros per bottle filling. So if we go high and charge 9 euros per bottle filling, the pure purchase price is amortized from 460 fillings (additional costs per filling are not included). If we divide that by two due to the buddy system, as a year-round diving buddy team, after 230 dives together, we reach the point where filling the tank only accounts for the additional costs (plus changing the filter five times). If you want to put it into perspective. All of this is a few euros cheaper: If you switch to the 140-liter electric motor version, the device only costs 3,190 euros, thus reducing operating and additional costs even further. Conclusion From our point of view, the epitome of diving freedom is a mobile compressor. Can be used anytime and anywhere (petrol version), easy to transport and powerful enough to replenish the breathing gas supply during surface breaks, this part makes the dream of independence come true to some extent. In this case, the Nautic Pro 150 did not disappoint. Respect to the manufacturer, who immediately took our small points of criticism seriously and corrected them. From now on the test model is chugging along with professional divers.

Test report by Alexander Kassler, editor-in-chief of the magazine “Tauchen” issue no.: 3/24.