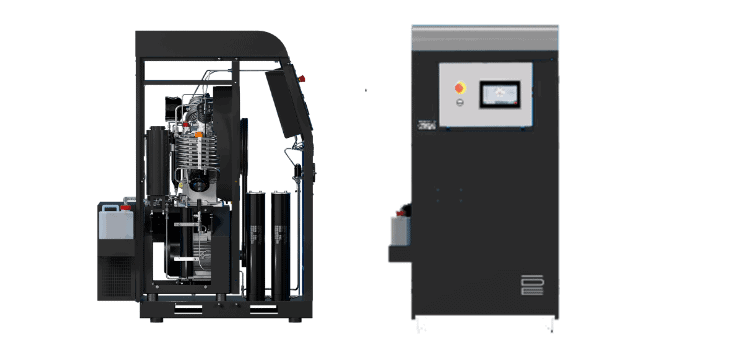

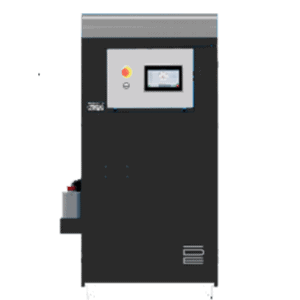

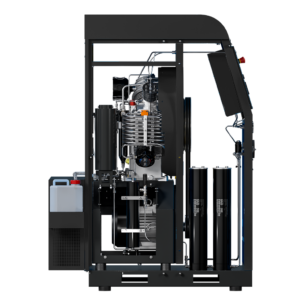

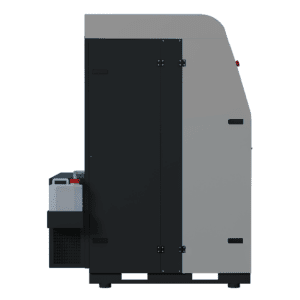

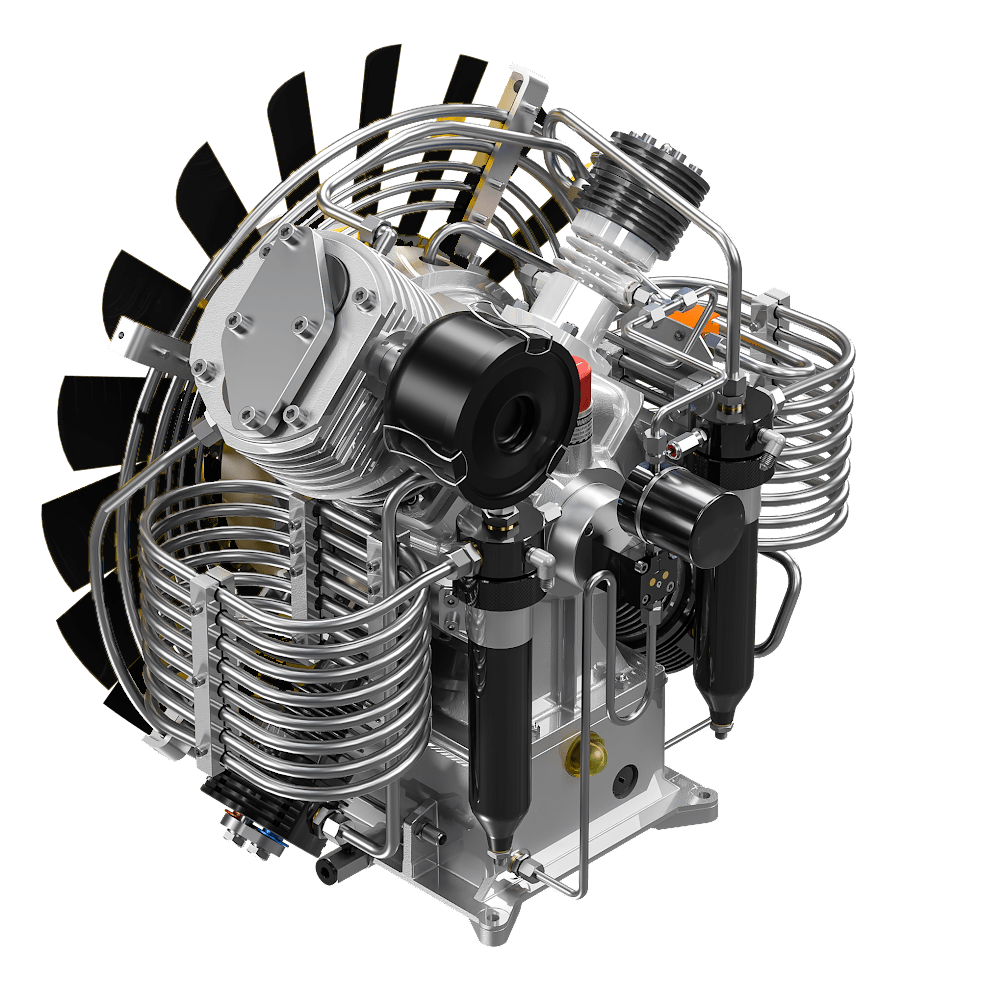

Consistently designed for high delivery performance and user-friendliness, equipped with the world's most advanced compressor block generation from IDE compressors, this system impresses with its features, compactness and extremely quiet running. The closed frame construction offers noise reduction (68 db(A)) and optimal protection for the operating personnel. If necessary, the systems can also be retrofitted with external filling strips and storage batteries.

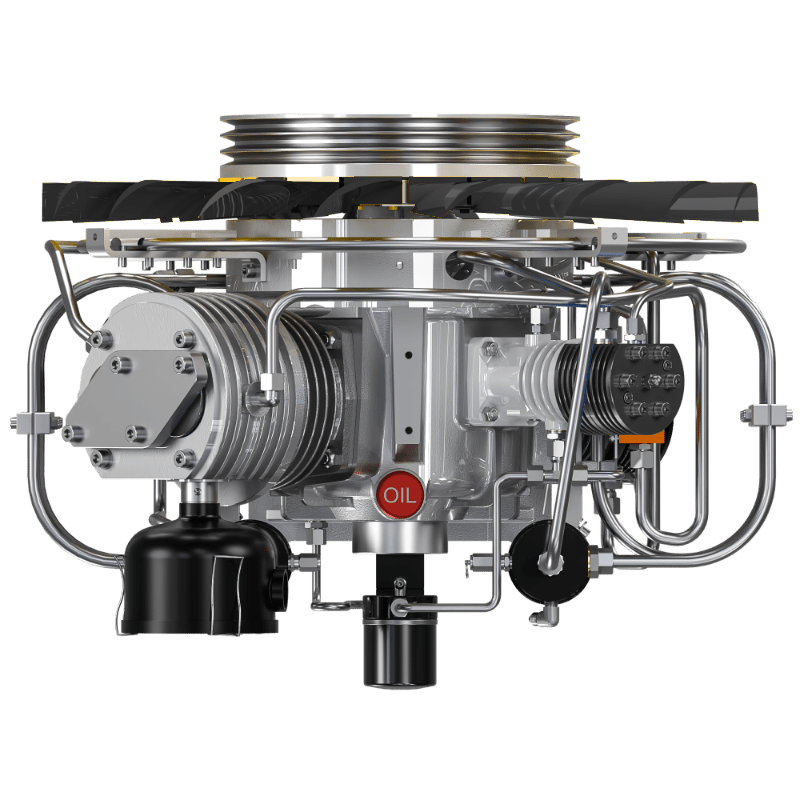

The TVCS series 450-550 offers you the FT-410/dryer system with a dryer housing made of a special aluminum alloy for approx. 1,400 m³ of treated air volume @20°C dryer housing temperature, which is designed for a final pressure of up to 420 bar. The FT-810 dryer system of the TFVS series 650-850L for approx. 2,500 m³ of treated air volume, which is designed for a final pressure of up to 420 bar. Through a service door on the side, the dryer unit can be optimally accessed for a filter change and the dryer cartridge can be changed in the shortest possible time. Another advantage is the additional cooling of the dryer by placing it in the cooling air flow.