Continuous monitoring of residual oil content VOC and in aerosol form(droplets).

Process and product safety 365 days / 24 h.

No sampling and laboratory evaluation necessary

permanent measurement in the online procedure

Total residual oil content (DIN EN 12021)

Calibrated range; 0.5 or 0.1 mg/m³ depending on customer requirements

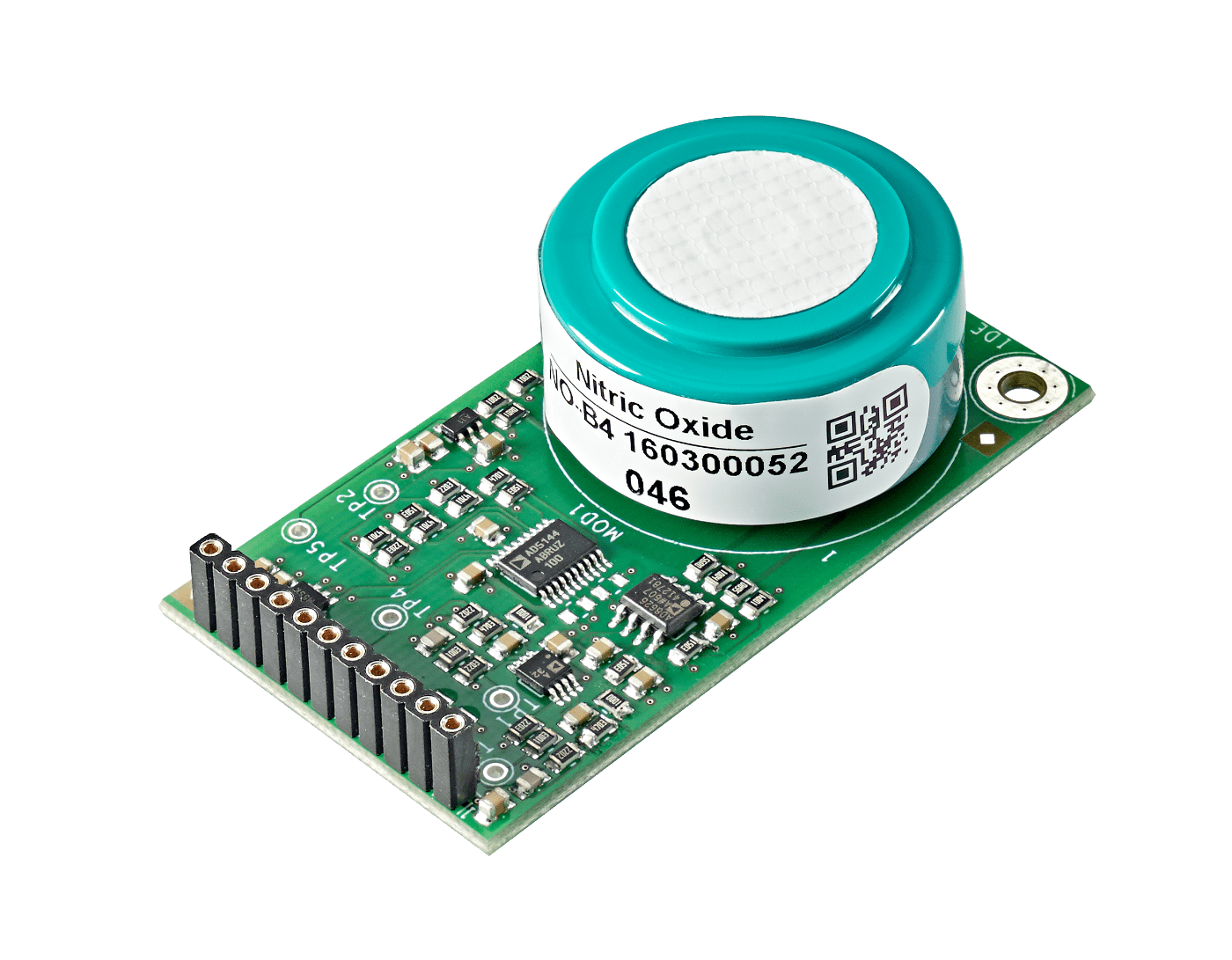

Medium: for compressed air

Measured variable: mg/m³ on normal conditions 1 bar and 20°C

Operating temperature: 0 to +50°C

Operating overpressure: max. 6 bar (g)

Operating conditions: vibration-free

Probe connection: push-in connection for Teflon hose AD 4 mm

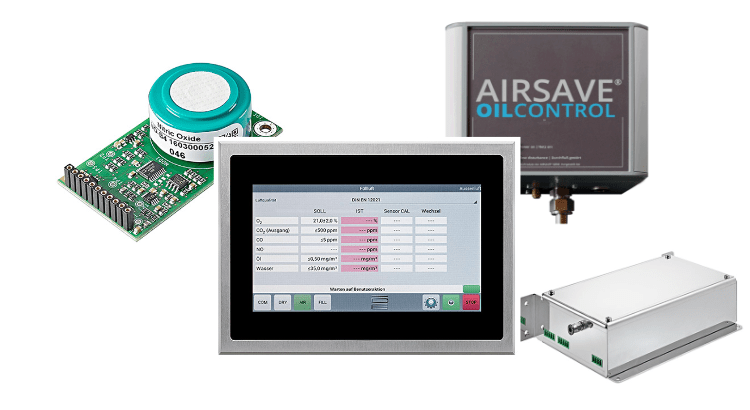

Measuring cell (transmitter)

Analog output: 4...20 mA (0.01 - 99.99 mg/m³, active, galvanically isolated

Housing: Die-cast aluminum

Housing dimensions: (W x H x D): 120 x 150 x 90 mm (without sample connection)

Weight: approx. 1 kg

Measuring cell supply to be provided by the customer:

24 VDC: min. 600 mA

Scope of delivery:

1 x connection cable with open ends (max. 5 m)

1 x instruction manual, german

1 x Manufacturer certificate