Advantages

independent of the location

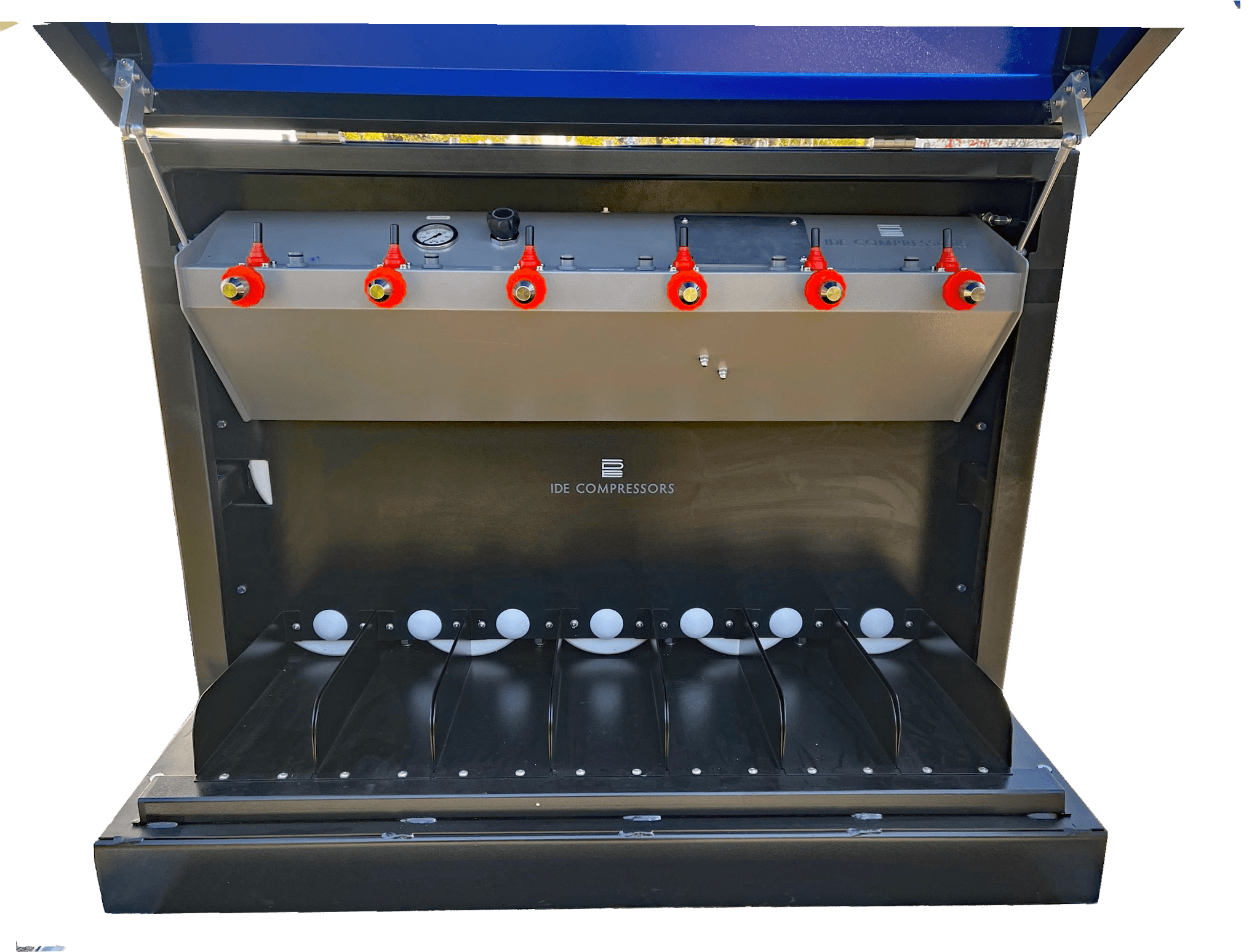

The IDE-FillQuick Mobile system works location-independent and is primarily designed to quickly and reliably fill respiratory protective devices with the purest breathing air, even in areas with contaminated air and heavily smoky environments. A system that is ideal for providing refinery, mine and construction site workers with a safe escape route in an emergency and for providing firefighters with fresh breathing air underground. With the filling panel, six respiratory protective devices can be filled simultaneously and independently of each other. The system is intuitive to use and only requires brief training for the filling staff. A special connection enables the connection of a filling hose up to 100 m long with a 6-part filling spider in order to be able to fill up to 6 respiratory protective devices at the same time, even at greater distances. The system can also be connected to an existing breathing air supply system via this connection.

Connect, start, ready to go

The IDE FillQuick Mobile Station can either be transported to the site of use on a transport trailer or placed at key, easily accessible points underground, where it allows the respirator wearer to quickly and easily fill their respirator without the help of an external filling service. Within a very short time, a 6 or 9 L 300 bar breathing apparatus is filled and use can continue. The refilling process takes place through a high-pressure compressor connection on the outside.

Cost and time saving

The number of respirators that need to be kept in stock is significantly reduced by using the IDE FillQuickMobile system, which in turn leads to significant cost savings in procurement, cleaning and maintenance as well as lower testing costs.

During the entire operation, the breathing apparatus remains with the respirator wearer so that his work does not have to be interrupted to change the equipment. This saves valuable minutes of operation, which can be life-critical when rescuing injured persons.

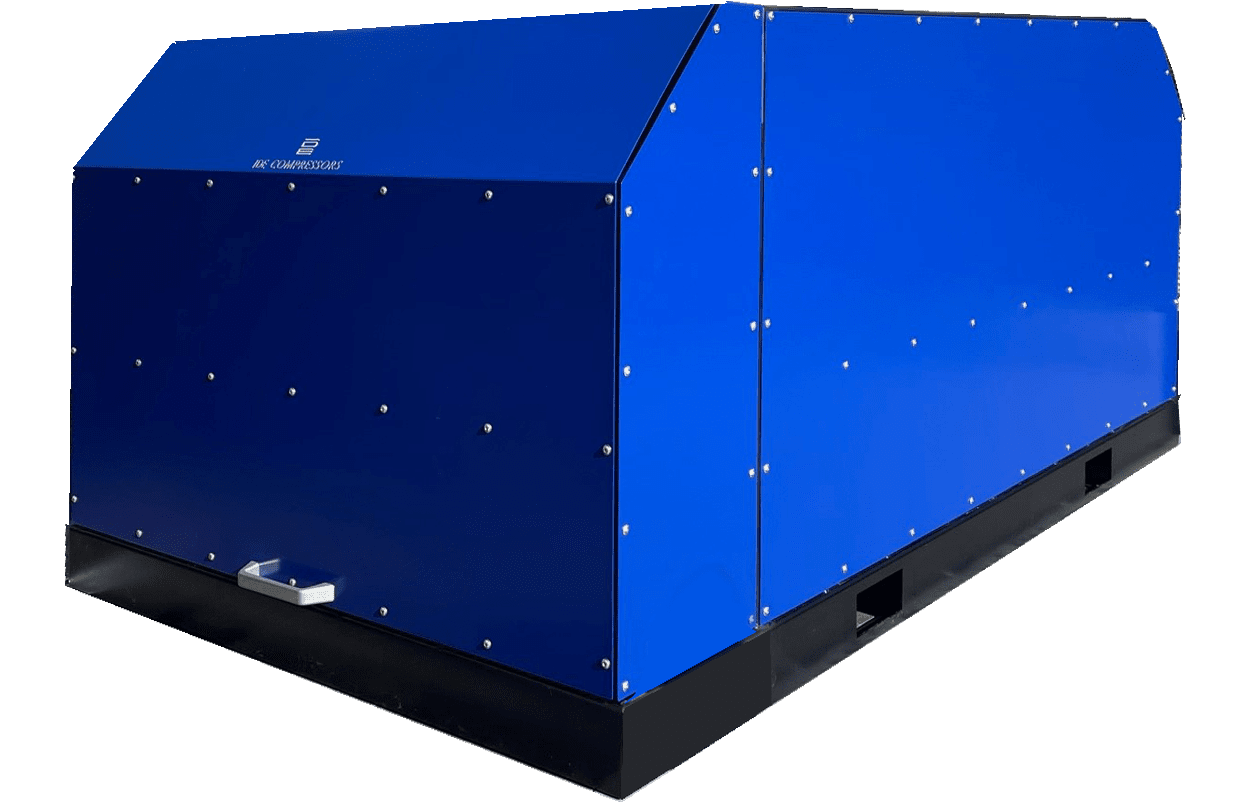

Extremely robust construction

The extremely robust construction enables easy and safe transport. On request, IDE also supplies the system with the matching trailer.

Slots have been made in the stable, torsion-resistant frame for handling with a forklift, so that the entire system can be lifted from all sides. If desired, stable threaded eyelet brackets can also be attached to the 4 upper corners, making loading with a crane e.g. B. enable on a ship or an offshore platform. The entire piping consists of seamless stainless steel high-pressure pipes (10 x 2 mm 580 bar), which are laid in a vibration-proof manner to avoid later leaks. An additional central shut-off valve secures the entire system during transport.

The complete system is splash-proof and the filling ramp is closed and secured with a hood. After opening the hood, it also serves as rain protection and protection against falling parts.

Long maintenance intervals

The IDE FillQuick Mobile only requires annual maintenance of the filling ramp with leak test and a repeat test of the storage cylinders every 5 years. An IDE service partner near you can perform these few maintenance tasks in the shortest possible time.