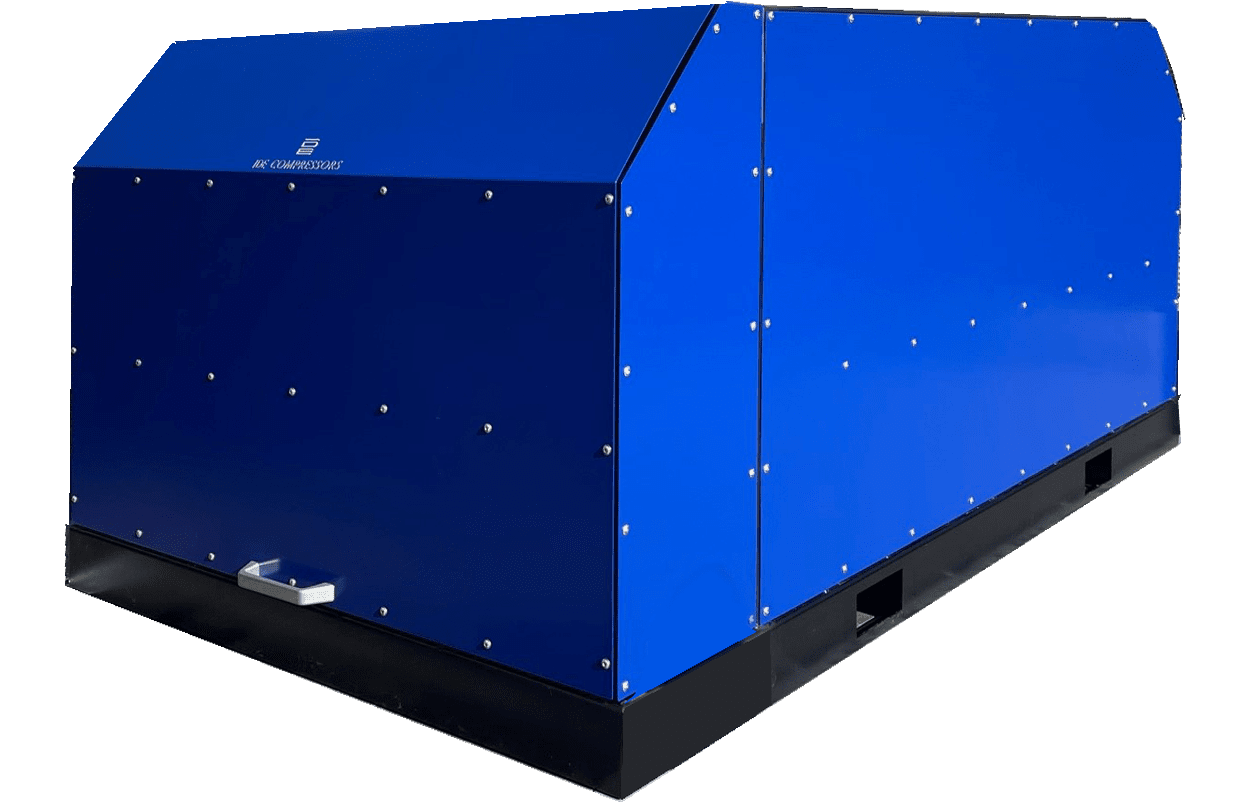

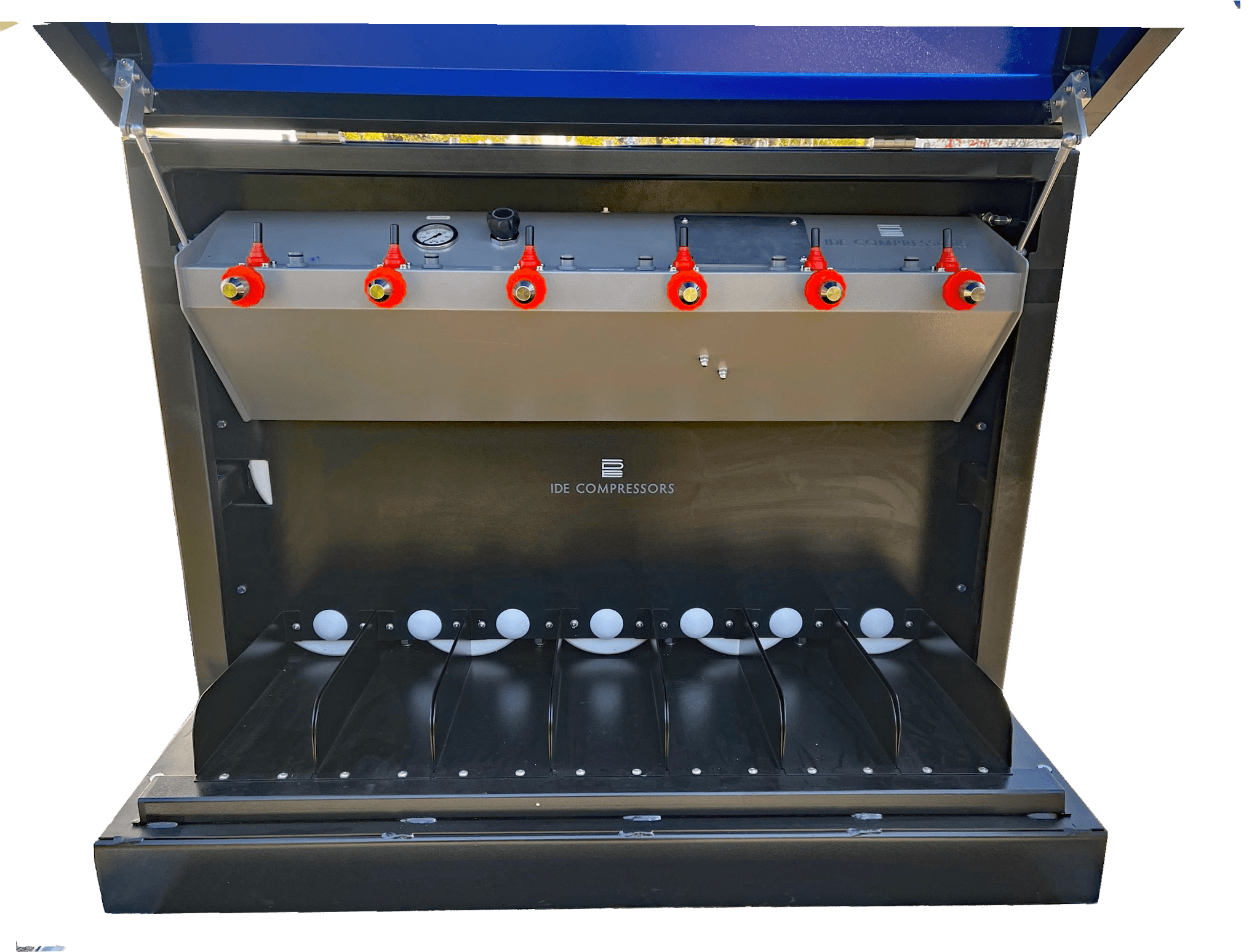

The IDE FILL QUICK MOBILE is an innovative filling station for large fire and mining disasters. The system with its integrated 6-fold filling ramp enables very fast filling of a very large quantity of respirators on site. This significantly reduces the amount of respirators that need to be kept on hand. The benefits are enormous: cost savings in procurement, cleaning and maintenance as well as lower testing costs.

Menu