Menu

Our current COMPETITION: Great prizes for divers and fire departments.

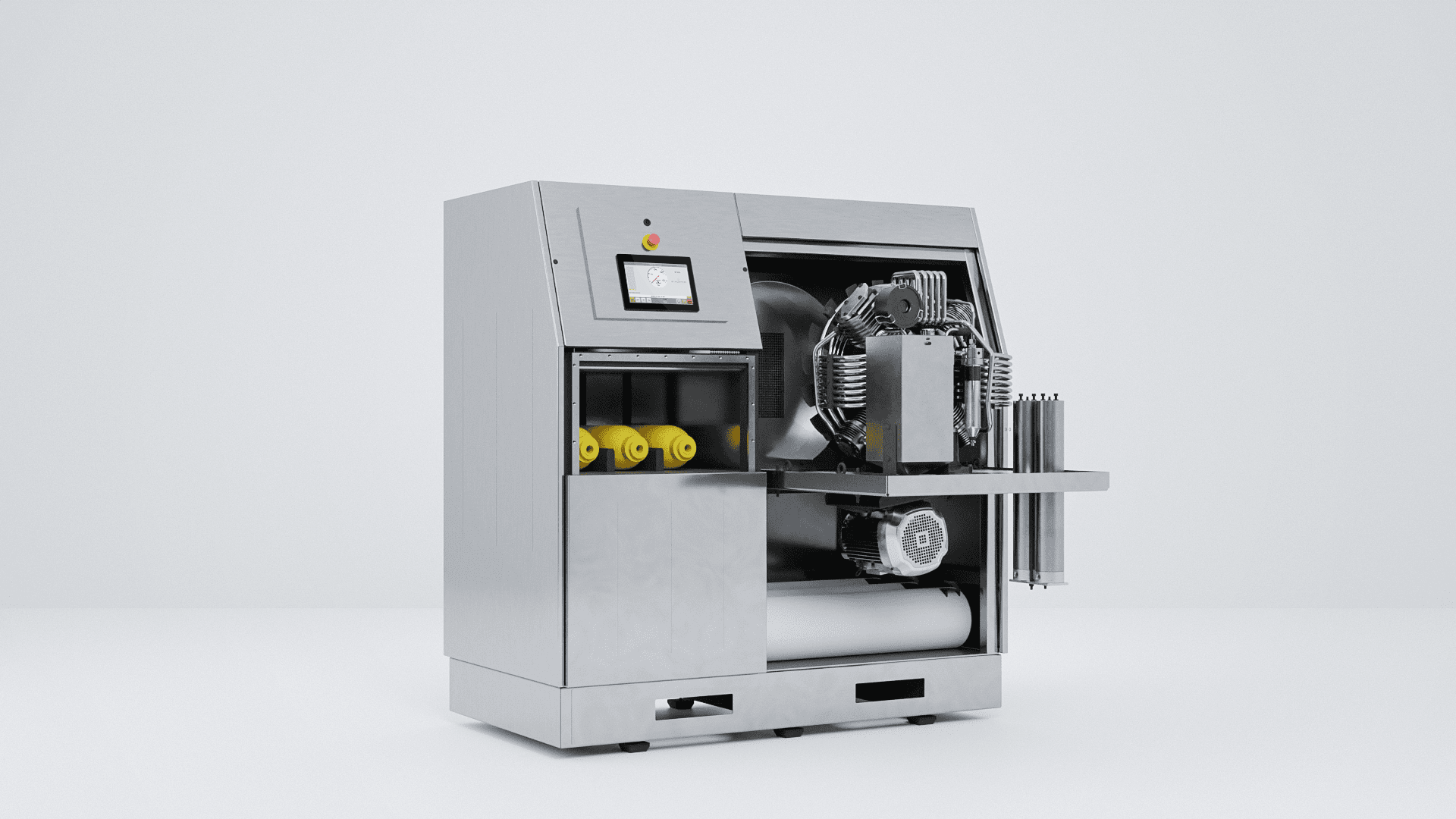

The TVCCF is the latest model from our company and can be operated with a pressure of 150-420 bar - can be ordered with an air liter capacity of 400-850 L/min.

The complete filling system impresses with its comfortable, intuitive control and particularly easy, safe handling. Unsurpassed maintenance-friendly, as the complete compressor unit with the filter towers is moved out to the front for filter cartridge changes or compressor service and maintenance. The entire cabin is soundproof and even in the most powerful version it does not reach 70 db(A).

A safety filling box with three filling positions integrated into the system protects against bottle bursting during the filling process. When designing them, particular emphasis was placed on safe and comfortable handling. To make handling even easier and safer, the box opens and closes electrically and fully automatically using a special safety circuit. The bottles are placed in the safety filling box at a height of 80 cm and connected without any effort. The filling box is completely depressurized for loading and unloading; only after closing the front door is the box pressurized and the filling process can be started.

The complete system including the safety filling box is controlled with the IDE TCC HMI Control. The TCC HMI control is currently considered to be the most modern, fully electronic Can-Bus control with a 7" Gorilla Glass color touchscreen.

Brackets for three 50L are integrated in the base frame of the system.

The complete system includes three 50 liter intermediate storage bottles with either 350 or (optionally 450 bar) working pressure with integrated priority filling control.

Breathing air in accordance with international standards, when used and maintained as intended in accordance with the manual and the use of a CO2 pre-filter if the CO2 concentration in the intake air is above the limit value.