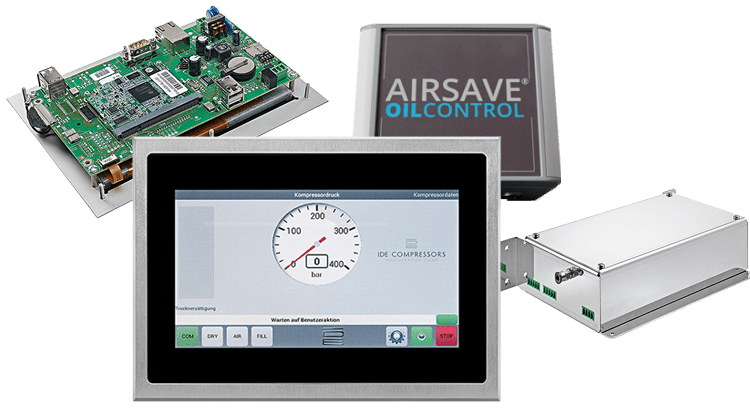

State-of-the-art compressor and filling system control that helps save energy and thus contribute to environmental protection. A highly sensitive scratch-resistant GFG 7" glass resistive touch screen with intuitive functional design.

Our compressors will be equipped with this control from the 2017 model series.