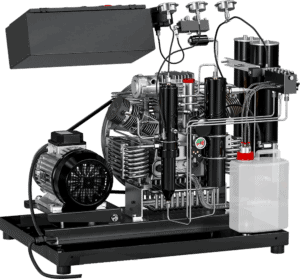

In response to numerous customer requests for a smaller stationary filling system, we have a new one TFI model added to our portfolio. An absolutely robust, reliable and low-maintenance professional filling system with an excellent performance balance and energy efficiency. And the best thing: we are the only manufacturer in the world to offer a 3-year guarantee.

Frame and cabin:

- 2 - 4 mm powder-coated sheet steel. Color: RAL 9005. Maintenance-friendly flaps on both sides.

- Noise insulation through heat- and oil-resistant special insulation 20 mm, decoupled from the floor using shock absorbers.

- Compressor unit and drive unit decoupled from the base frame using oscillating elements.

Technical data compressor unit:

- Air liter output: 320 l/min = 19.2m³ - 11.3 CFM

- maximum working pressure: 420 bar

- Revolutions / Min. 1580

- Compressor block, completely made of aluminum with aluminum cylinders.

- Safety valves after each compressor stage.

- Type-tested and TÜV-tested ultimate pressure safety valve.

- Robust rolling bearings (not ball bearings)

- Cylinder liners made of aluminum with NICASIL coating.

- 3 compressor stage with free-flight pistons and special piston rings.

- Intercooler lines made from special stainless steel alloys.

- Micronic intake filter

Lubrication:

- Double lubrication with maintenance-free low-pressure oil pump with metal micro-particle oil filter as well as sling pin lubrication with two counter-rotating oil sling pins, oil volume 2 liters

Air-gas treatment:

- Micronic intake air filter, intermediate separator after 1st, 2nd and 3rd compressor stage, 5 liter collecting container.

- FT 410 three-stage breathing air dryer system, dryer capacity approx. 1200 m³ at 20° C filter wall temperature.

- The dryer saturation is monitored using Airsave PRO E, a moisture sensor integrated into the filter cartridge for dryer cartridge monitoring in the dryer housing.

- Optionally, the air quality can be monitored using AIRSAVE ULTIMATE, a monitoring system integrated into the compressor for dryer cartridge monitoring in the dryer housing, absolute humidity in mg/m³, dew point, CO content, CO² content and O² content of the compressed gas and controls the compressor.

- An oil sensor can also be optionally switched on for all oils, including residual oils up to 0.001 mg/m³.

- The ambient air to be sucked in can also be optionally monitored for CO2, SO2 NO and flammable gases. Cylinder arrangement: W shape

- Intermediate separator 1, final separator 1

- Safety valves for each compression level

Lubrication:

- Low pressure gear oil pump with oil filter + additional sling pin lubrication

Control:

- IDE HMI- High ERfficient, control

- Monitor. u Controlling the final pressure, which can be infinitely adjusted on the display,

- Control and monitoring of the automatic condensate drain system,

- the level of the lubricating oil in the crankcase,

- Control and monitoring of the star/delta motor control,

- optional monitoring of the breathing air dryer cartridge change intervals with shutdown,

- Monitoring the amps during operation to avoid damage to the system,

- the direction of rotation (phase sequence),

- the temperature in the compressor silent cabin,

- optional - control and monitoring by AIRSAVE ULTIMATE air quality monitoring.

Drive:

- Asynchronous three-phase motor IE3 400 V, 50 Hz, 5.5 kW, B3 IP 55, taper drive belt pulley with SPA V-belt.

Filling system:

- 2 filling hoses with ventable safety filling connections DIN 300 bar

Accessories included:

- Dryer housing key, detailed operating manual, parts manual, compressor log book, compressor filling book, declaration of conformity.

- Certificates for safety valves, hoses, separators, dryer unit, air quality and leak testing.

- Dryer cartridges 1 x FT 410 A

- Dimensions: LWH 1100 x 720 x 900 mm, weight approx. 190 kg.